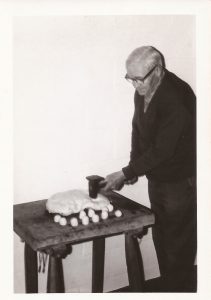

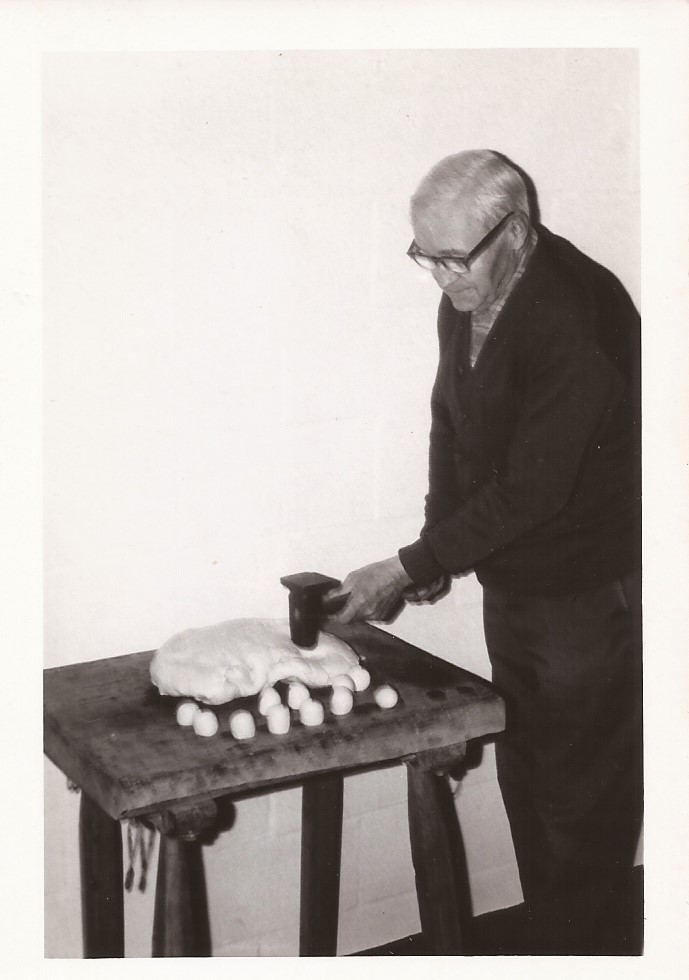

If you don’t know by now, the “beaten” in beaten biscuits is literal. You can read our FAQ page for more details, but the short explanation is that the biscuit dough must be beaten with some sort of blunt instrument for 30 minutes (for family) to 45 minutes (for company) to incorporate air into the dough prior to forming the individual biscuits. While there is no definitive tool to use to beat the dough, traditionally baseball bats, big sticks and the back side of axes were common. In the Orrell family the tool of choice has been a 5 pound blacksmiths hammer for the last 80+ years.

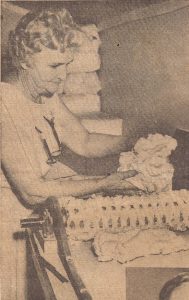

Now, unless you are the Hulk, you are thinking right now, “That is sure a lot of work!”, which it most certainly is. During the industrial revolution someone decided that there must be a better way and the “roller” was born. This fairly simple device consists of a cylinder with large teeth and a crank handle attached to a table or other flat surface. The dough was passed between the roller and table, causing indentations to be made in the dough, similar to the beating process. The dough is then folded over and the process repeated.

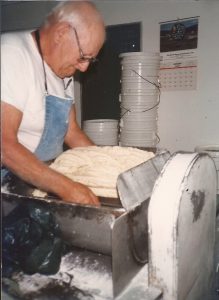

While still manually operated, this method of beating is much easier on the arms. Eventually people added electric motors to the roller taking all of the manual labor out of the process. At Orrell’s Maryland Beaten Biscuit Company we used a custom-made stainless steel roller manufactured by Olin Tull in 1948.

Run by an electric motor, this machine will make up to a 40 lb batch of dough, enough to make 30 dozen biscuits. This same machine was used to beat all biscuits the company produced until it was closed down and is still kept in working order today.

As you can see, the history of the beaten biscuit not only includes culinary innovation, but mechanical innovation as well. But through all of this, one thing has not changed; the time. No matter the method you use, it takes 30 to 45 minutes to beat the dough. As they say, “Good things come to those who wait”.

You must be logged in to post a comment.