The Evolution of Beating Biscuits

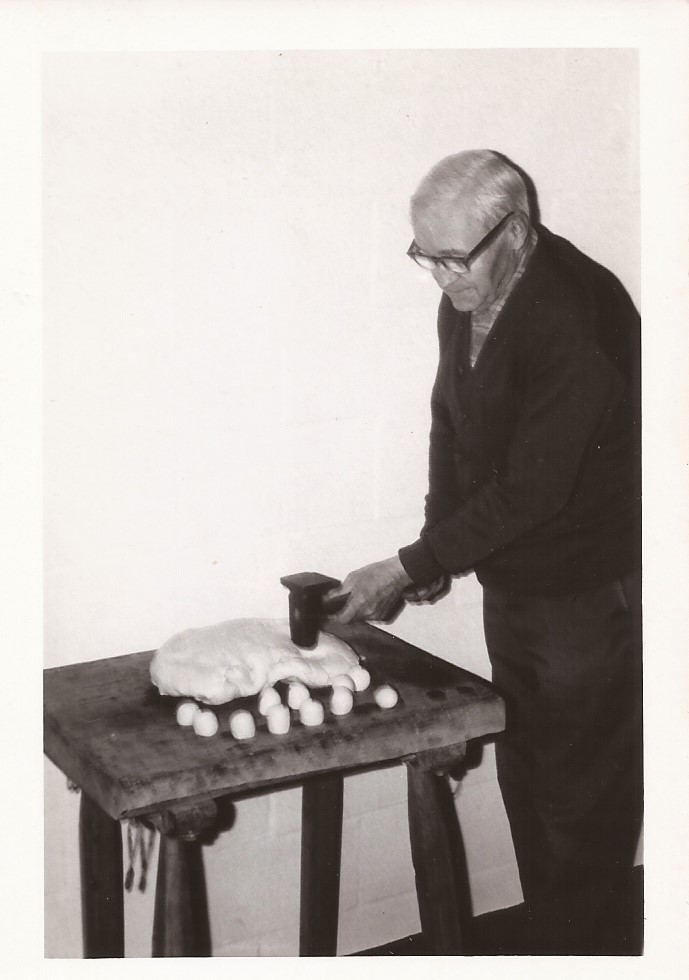

If you don’t know by now, the “beaten” in beaten biscuits is literal. You can read our FAQ page for more details, but the short explanation is that the biscuit dough must be beaten with some sort of blunt instrument for 30 minutes (for family) to 45 minutes (for company) to incorporate air into the […]